Automated Cutting Machines

-

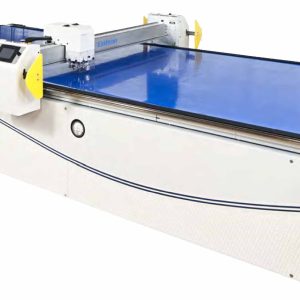

EAGLE S125

Eastman’s static table system is capable of cutting, marking, drilling and punching virtually any flexible material at speeds of up to 60 inches per second (152.4 cm/sec.). The static cutting table has proven itself as the go-to resource for materials like cotton, nylon and vinyl as well as difficult-to-cut materials—such as polystrand, p-tex, and fiberglass-polyester blends. The static table system is available in a range of system lengths and widths to meet the demands for prototypes, one-offs and full-production runs. The system’s high-precision configuration features multi-axis motion for more defined and accurate cuts. Material is spread across the static table by an operator or with the use of a pneumatic gripper bar. The open plenum vacuum system design ensures evenly dispersed airflow for optimal material hold-down. This computer-controlled system features zoning capabilities to enable cutting in one area while the operator is simultaneously picking parts in another, maximizing daily production capacity. Additional Information -

EAGLE_C125

Taking Continuous Cutting to New Heights The Eagle conveyor system boasts supreme capabilities for single- to low-ply cutting requirements. It has the ability to continuously convey rolled material goods with consistent speed and control. Eastman's gantry and tool head design are engineered to cut the most diverse technical and industrial fabrics available, while exceeding industry standards for accuracy Additional Information -

EAGLE_SL_COMBI

The Eastman combination laser and cutting system offers a laser for cutting fabrics that require a fused edge as well as the proven, reliable technology of Eastman’s static cutting table. The tool head is equipped with a 200 watt gas assist laser (100 watt optional), three individually aligned and calibrated tool spindles, and a pneumatic pen/marker holder. Additional Information