Shop By Brand

Industrial Sewing Machines

-

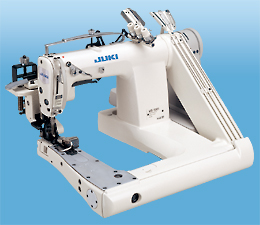

MF-7900

High-speed, Cylinder-bed, Top & Bottom Coverstitch Machine Additional Information -

MF-7500

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. The front cover is trimmed to allow operators to bring their hands closer near the needle entry area, thereby increasing work efficiency in the covering process, etc. -

MF-7200D

The sewing machine is applicable to the sewing of sleeve cuffs, necklines, and children's wear. Small-cylinder-bed, Top, and Bottom Coverstitch Machine Semi-dry-head, small-cylinder-bed, top and bottom coverstitch machine has been added to JUKI's product lineup. The small cylinder-bed and semi-dry head features have been achieved while placing priority on ease of use. The sewing machine supports comfortable "sewing" work. Additional Information -

MF-3620

A servomotor is installed on the machine head for adopting the direct-drive mechanism. The power consumption has been reduced by approximately 52 % as compared with the conventional model. Since the sewing machine provides superb responsiveness, the material can be controlled as desired when sewing a curve part. In addition, the belt-drive type sewing machine (when a servomotor is used) has also had its power consumption reduced by 32 %. Additional Information -

JUKI AMS-251

High-end, single needle CNC sewing machine, machine-head-turning mechanism, high-quality seams uniformly in every sewing direction. Best in stitches 360, Sewing are of 1000x600mm Additional Information -

AMS-224EN

The machine achieves the highest sewing speed of 2,500sti/min among those with a similar sewing area. With its higher productivity, the machine performs various kinds of stitching making the most out of its wider sewing area in various sewing applications such as attaching handles to bags and pouches, attaching belts, sewing many small parts at a time, attaching parts to shoes, and sports shoes (one pair of shoes) and sewing airbags. Additional Information -

AMS-221EN-3020

Computer-controlled cycle Machine with Input Function, Size 300x200mm Additional Information -

AMS-221EN-2516

The sewing machine achieves the highest sewing speed, 2,800sti/min, in the industrial sewing machine industry. As a result, the cycle time is reduced. The feed accuracy is substantially improved due to the adoption of the encoder control system. The new AMS series models substantially decrease power consumption when compared with the conventional ones. They have designed to achieve eco-friendliness. Additional Information -

AMS-210EN

The sewing machine flexibly supports the sewing of small articles such as labels and emblems. The sewing machine's small sewing area promises ease of use when handling small articles, thereby enabling smooth sewing operation. Additional Information -

MS-1261

Computer-controlled cycle Machine with Input Function, Size 220x160mm Additional Information -

MS-1190

Both needle thread tension and bobbin thread tension have been decreased after reinvestigation of the double chainstitching mechanism. Furthermore, the stitch dial, gauges, and looper have been dramatically improved, thereby forming beautifully finished seams and preventing puckering. Additional Information -

MP-200N

In addition to balloon-stitching (to produce seams with a hand-stitched touch), smooth sewing of chain-off stitches, and having other outstanding seam quality features of the highly regarded Columbia 100, the MP-200N achieves more improved sewing capabilities and a wider adjustment range. Additional Information -

MH-486-5(4)

The machine comes with a thread spreading mechanism and an adjustable needle guard to prevent stitch skipping. The thread clamp mechanism, tension release mechanism, and needle thread draw-out mechanism enable the machine to leave a thread of a uniform length after thread trimming and prevent slip-off of the needle thread. All of these mechanisms contribute to upgraded sewing. -

MH-484-5(4)

The machine comes with a thread spreading mechanism and an adjustable needle guard to prevent stitch skipping. The thread clamp mechanism, tension release mechanism, and needle thread draw-out mechanism enable the machine to leave a thread of a uniform length after thread trimming and prevent slip-off of the needle thread. All of these mechanisms contribute to upgraded sewing. -

MH-484

The machine comes with a thread spreading mechanism and an adjustable needle guard to prevent stitch skipping. The thread clamp mechanism, tension release mechanism, and needle thread draw-out mechanism enable the machine to leave a thread of a uniform length after thread trimming and prevent slip-off of the needle thread. All of these mechanisms contribute to upgraded sewing. -

MH-481-5(4)

The machine comes with a thread spreading mechanism and an adjustable needle guard to prevent stitch skipping. The thread clamp mechanism, tension release mechanism, and needle thread draw-out mechanism enable the machine to leave a thread of a uniform length after thread trimming and prevent slip-off of the needle thread. All of these mechanisms contribute to upgraded sewing. Additional Information